Master Printing on Ribbon: Tips & Techniques for Stunning Results

Adding custom printing on ribbon does more than just tie a bow; it turns everyday items into cherished keepsakes. It can give your products a polished, professional finish or add a uniquely personal touch to a gift. It’s a wonderfully versatile craft that closes the gap between simple packaging and sophisticated branding, making it a secret weapon for businesses and creative folk alike.

The Enduring Appeal of Custom Printed Ribbon

There’s just something special about an item finished with a custom printed ribbon, isn't there? It elevates the whole experience, whether you're unboxing a product from a beloved brand or receiving a beautifully wrapped gift. It's a small detail that speaks volumes about care, quality, and thoughtfulness.

There’s just something special about an item finished with a custom printed ribbon, isn't there? It elevates the whole experience, whether you're unboxing a product from a beloved brand or receiving a beautifully wrapped gift. It's a small detail that speaks volumes about care, quality, and thoughtfulness.

For a business, it’s a brilliant branding tool that reinforces your identity right when a customer is most engaged. For the rest of us, it makes celebrations like weddings, birthdays, and anniversaries feel that much more special and bespoke. It’s this mix of commercial savvy and personal sentiment that gives printed ribbon its lasting charm.

From Historic Mills to Modern Desks

Printing on textiles has deep roots right here in the UK. The whole industry went through huge technological shifts during the 19th and 20th centuries. Government records from around 1846 show there were over 100 printworks in the Manchester area alone, with many more in places like Essex and Kent. These mills churned out all sorts of printed textiles, including ribbons for fashion and decoration.

Fast forward to today, and technology has made ribbon printing more accessible than ever. What once demanded massive industrial machinery can now be done with desktop printers. This has opened up a world of possibilities for small businesses, event planners, and even hobbyists.

A well-chosen ribbon doesn't just hold a package together; it ties your brand story to a tangible, positive experience for the customer. It's often the first and last physical touchpoint they have with your product.

Why Invest in Personalised Ribbon?

The benefits of using custom ribbon are clear and powerful. It can help you stand out in a crowded market or simply add that unforgettable touch to a special day. Before you jump in, though, it’s worth thinking about the key things that will shape your final design.

Here are a few core elements to consider:

- Brand Perception: A professionally printed ribbon makes a small business look incredibly polished and detail-oriented.

- Event Cohesion: Imagine matching ribbons across your invitations, favours, and décor. It creates a beautifully seamless theme for a wedding or corporate event.

- Product Enhancement: It adds a touch of luxury to packaging for items like cosmetics, chocolates, or handmade crafts.

Thinking through what you want to achieve is the perfect first step. Our team is always here to help, and our personalised ribbon printing services can guide you through all the options to bring your vision to life.

Choosing the Right Ribbon for Your Project

The very first decision you’ll make when printing custom ribbons is also the most important: the material. It’s the canvas for your design, and its texture, feel, and finish will completely define the final product. Getting this right is the foundation of a beautiful result.

Think of it this way: are you going for a sleek, luxurious feel for high-end packaging? Or maybe something a bit more rustic and textured for handmade gifts? The material you pick sets the entire tone.

Understanding Your Material Options

Different ribbons have their own unique personalities, and each one shines with certain printing methods. Let's get to know the main players.

Satin Ribbon: This is the go-to for so many projects, and it's easy to see why. That smooth, glossy surface is a dream for printing crisp, clear designs. You can get single-faced satin (shiny on one side) or double-faced, which is glossy on both and has a much more premium feel. From my experience, double-faced satin and thermal printing are a perfect match for delicate text and intricate logos.

Grosgrain Ribbon: You’ll recognise grosgrain by its signature ribbed texture. This gives it a lovely matte finish and a sturdier feel. That texture adds a wonderful character to printed designs, making it a fantastic choice for screen printing. The ink settles beautifully into the ribbed surface for a charming, high-quality look.

Organza Ribbon: Sheer, lightweight, and incredibly delicate, organza is all about elegance. Its see-through quality creates a dreamy, ethereal effect that’s perfect for wedding favours, fancy floral arrangements, or sophisticated gift wrapping. Printing on organza needs a delicate touch; methods like hot foil stamping can produce stunning metallic designs that seem to float on the fabric.

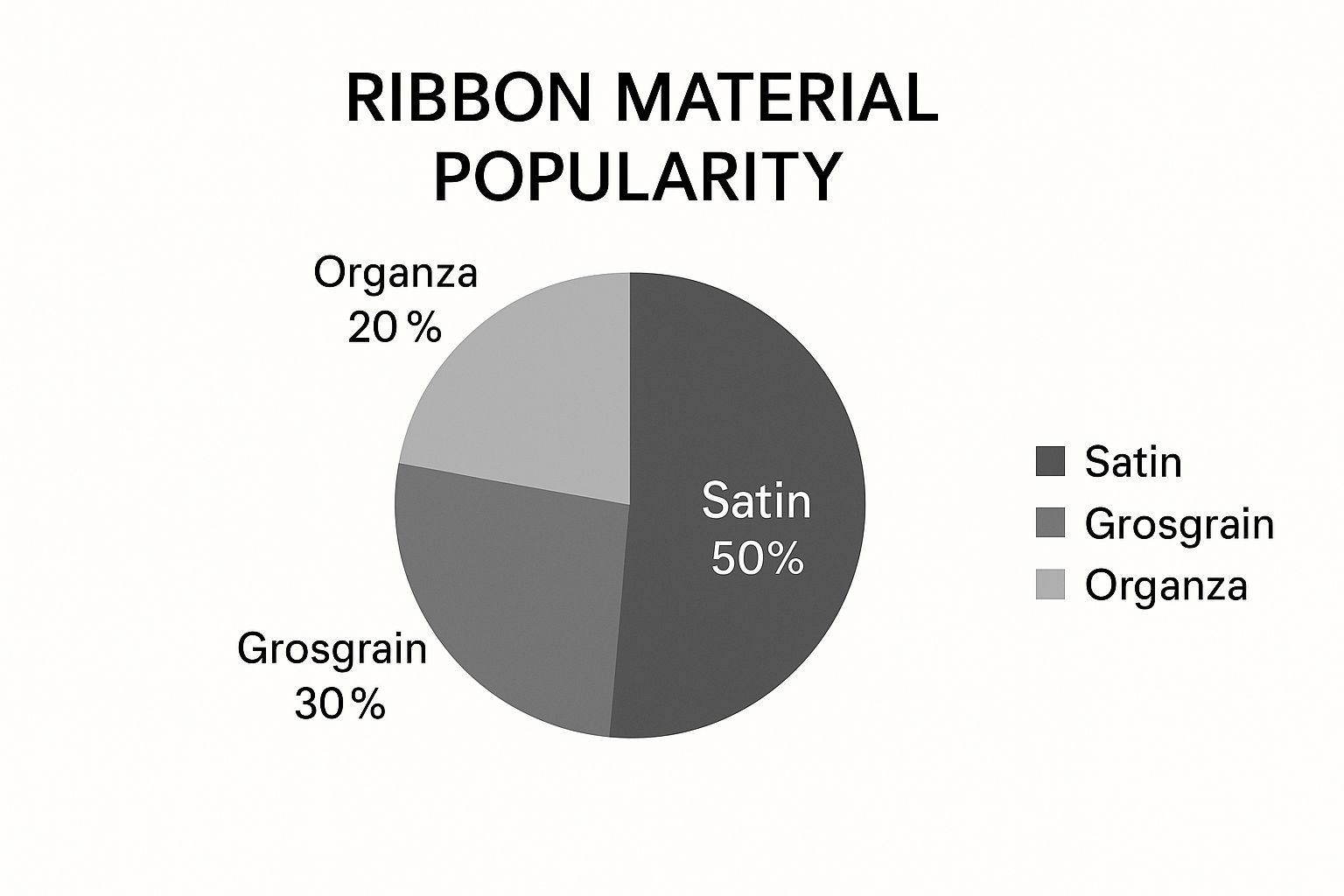

To help you visualise this, here's a quick look at the most popular materials we see used for custom printing.

As you can see, satin's versatility makes it a clear favourite, but the unique textures of grosgrain and organza are still highly sought-after for achieving specific creative goals.

Matching Ribbon Material to Your Print Method

To make things even clearer, choosing the right combination of ribbon and print technique is key to getting the look you want. Some pairings just work better than others.

This table should help you find the perfect match for your project.

| Ribbon Material | Best For Printing Method(s) | Key Characteristics | Ideal Use Case |

|---|---|---|---|

| Satin | Hot Foil Stamping, Thermal, Screen Printing | Smooth, glossy, vibrant colour base | Luxury packaging, wedding favours, corporate branding |

| Grosgrain | Screen Printing, Hot Foil Stamping | Ribbed texture, matte finish, durable | Gift wrapping, product tags, craft projects |

| Organza | Hot Foil Stamping, Delicate Thermal | Sheer, lightweight, ethereal | High-end floral arrangements, wedding decor, delicate gifts |

| Cotton | Screen Printing, Digital Printing | Soft, natural texture, matte look | Eco-friendly brands, rustic themes, handmade goods |

By cross-referencing your desired ribbon with the printing methods it suits best, you can ensure your final design looks professional and intentional.

Matching Ribbon to Your Purpose

Always think about the ribbon's final destination. A ribbon that’s going to be a durable wristband for an event needs very different qualities from one tied gently around a box of artisan chocolates.

-

For Durability: If your ribbon needs to survive a bit of wear and tear—think lanyards or product tags—a tough material like polyester grosgrainis a brilliant choice. Its tight weave means it won’t fray easily.

-

For Luxury: When presentation is paramount, nothing beats a high-quality, double-faced satin ribbon printed with a gleaming metallic foil. It immediately signals opulence and value.

-

For a Natural Feel: For eco-conscious brands or rustic-themed events, cotton ribbon is a superb option. Its soft, natural texture is the perfect partner for simple, bold prints.

The key is to let the ribbon’s purpose guide your material choice. A mismatch between the material and its end-use can undermine the final effect, no matter how good the print quality is.

For example, I’ve seen people use delicate organza for a heavy-duty packaging job, and it just doesn’t hold up. On the flip side, a standard polyester ribbon might not send the right message for a luxury brand. Just taking a moment to consider the context will ensure your creation is not only beautiful but perfectly fit for purpose.

Exploring Ribbon Printing Techniques

Once you’ve settled on the perfect ribbon, the next step is figuring out how to get your design onto it. The world of printing on ribbon isn’t a one-size-fits-all situation. Different methods give you vastly different results and are suited to different project scales and budgets.

Getting your head around these options is the key to matching your creative vision with a process that’s both practical and cost-effective. Some techniques are brilliant for quick, small-batch runs at home or for a small business, while others are built for large-scale production where you can't compromise on vibrancy and durability. Let's break down the most common methods so you can choose the right one for your project with confidence.

Thermal Transfer Printing

This is probably the most accessible way to get started, especially for small businesses and serious crafters. A thermal transfer printer uses a heated printhead to melt a coloured foil or resin directly onto the ribbon's surface. It's like a very precise, automated version of using a hot stamp.

It’s fantastic for creating crisp, sharp text and single-colour logos, particularly on smooth satin ribbons. An Etsy shop owner, for instance, could invest in a small thermal printer to add their branding to product packaging. This gives them professional-looking results without having to order thousands of metres at a time.

Key benefits of thermal printing include:

- Low Setup Cost: Desktop thermal printers are relatively affordable.

- Flexibility: You can print just a few centimetres or many metres at once, making it ideal for on-demand jobs.

- Speed: It’s a quick process for short to medium runs.

Where this method really shines is with metallic foils—golds, silvers, and rose golds. They create a stunning, high-end look with minimal fuss.

Hot Foil Stamping

For a truly premium, embossed finish, you can't beat the classic technique of hot foil stamping. Instead of using ink, this method uses a heated metal die to press a very thin layer of metallic or pigmented foil onto the ribbon. The combination of heat and pressure leaves a slight indentation, giving the design a tactile quality that just feels luxurious.

This is the perfect choice for elegant wedding ribbons, high-end corporate gifts, or any project where you want to communicate exceptional quality. It works beautifully on a wide range of materials, including satin, grosgrain, and even velvet, where its sharp definition really stands out.

The real magic of hot foil stamping is in its finish. The way the light catches the metallic foil creates a sense of depth and opulence that is difficult to replicate with other printing methods.

Screen and Digital Printing

When your design is more complex or involves multiple colours, screen printing and digital printing are the leading contenders.

Screen printing works by pushing ink through a mesh screen onto the ribbon. Each colour in your design needs its own separate screen, so it’s best suited for bold designs with one or two colours. It's incredibly versatile and produces a thick, durable layer of ink that sits on top of the fabric, which is a great choice for textured grosgrain ribbons.

Digital printing, which includes dye-sublimation, is your go-to for photographic quality and unlimited colours. With dye-sublimation, the ink is turned into a gas that actually permeates the polyester fibres of the ribbon. This means the design becomes part of the fabric itself, so it won’t crack, peel, or fade. It's the top choice for durable items like lanyards or washable garment labels where longevity is absolutely crucial.

If you're interested in a deeper dive, you can learn more by exploring the art of ribbon printing techniques with us in another detailed guide. Ultimately, this choice comes down to the complexity of your artwork and the scale of your production.

Preparing Your Artwork for Flawless Prints

A brilliant print finish starts long before the ribbon ever touches a printer. In fact, the quality of your digital artwork is probably the single most important factor in getting a crisp, professional result. Nail your design file from the get-go, and you'll sidestep common headaches like pixelated logos or disappointing colour shifts.

Think of your artwork as the blueprint for the final printed ribbon. Any flaws in that blueprint—no matter how small—will be faithfully reproduced on the finished product. A little prep work now will save you a ton of time, materials, and frustration down the line.

Vector vs Raster: The Critical Choice

The first big decision you'll face is choosing the right file format for your artwork. Your two main options are vector and raster, and for something as narrow as a ribbon, this choice is crucial.

-

Vector Files (AI, EPS, SVG): These are the undisputed champions for ribbon printing. Vector graphics are built from mathematical equations, not tiny squares of colour. This means you can scale a vector logo to any size imaginable—from a tiny detail to a massive banner—and it will never lose quality or look blurry. It's the secret to keeping your text and logos perfectly sharp.

-

Raster Files (JPEG, PNG, GIF): These images, like photos, are constructed from a grid of pixels. While they have their place, their resolution is fixed. If you try to enlarge a small raster image to fit a wider ribbon, you’re just making the pixels bigger, which results in that dreaded blocky, "pixelated" mess. If you absolutely have to use a raster file, make sure it’s created at a high resolution—at least 300 DPI (dots per inch)—at the exact size you intend to print it.

For the cleanest, most professional results on ribbon, always, always try to work with vector files. It gives you the most flexibility and is your best guarantee that text and logos will look exceptionally sharp every single time.

Designing for a Long, Narrow Canvas

Designing for a ribbon is a unique challenge. You're not working with a standard A4 page or a business card; you've got a very long, thin space to play with. This calls for a different creative approach.

Seamless Patterns

If you're aiming for a design that repeats continuously along the ribbon's length, you’ll need to create what’s known as a seamless pattern. This just means that the design on the right-hand edge of your artboard needs to line up perfectly with the left-hand edge. When it repeats, it creates a flawless, continuous flow with no awkward gaps or mismatched lines. Most good design programs, like Adobe Illustrator, have built-in tools to help you create and test these patterns with ease.

Text Legibility

When it comes to text, keep it simple and bold. Extremely fine, delicate, or ornate fonts can quickly become unreadable when shrunk down to fit on a narrow ribbon, especially on textured materials like grosgrain.

Stick to clear, legible typefaces and make sure they're large enough to be easily read from a reasonable distance. My best advice? Always print a small test strip to check the legibility before you commit to a full print run. It’s a tiny step that can save you from a costly and disappointing mistake, ensuring your message actually gets read.

Troubleshooting Common Printing Issues

Even with the most careful planning, printing on ribbon can sometimes hit a snag. It’s incredibly frustrating to see a smudged logo or a patchy foil transfer, especially when you’re up against a deadline. But don't worry—over the years, I've learned that most common issues have surprisingly simple fixes.

Even with the most careful planning, printing on ribbon can sometimes hit a snag. It’s incredibly frustrating to see a smudged logo or a patchy foil transfer, especially when you’re up against a deadline. But don't worry—over the years, I've learned that most common issues have surprisingly simple fixes.

This practical guide is here to help you diagnose and solve those little problems, saving you time, materials, and a fair few headaches. We’ll get your printing process running smoothly again.

Diagnosing Ink Smudges and Poor Adhesion

One of the most frequent complaints I hear is about smudged or blurry prints. If your design isn't coming out sharp, the culprit is often a mismatch between your settings and your materials.

For thermal transfer printing, this usually points to an incorrect heat setting on the printhead. Too much heat can cause the foil to melt excessively and bleed. Too little, and the foil won't transfer properly, leaving you with a weak or incomplete image.

Expert Tip: Start with your printer's recommended heat setting for your specific ribbon and foil. If you see smudging, dial the heat back in small steps until the print is crisp. For weak prints, do the opposite and nudge it up slightly.

Another common cause is using a foil that isn't compatible with your ribbon. Not all foils are made to stick to all materials. A foil designed for smooth satin might not adhere correctly to the ribbed texture of grosgrain, resulting in a flaky or uneven finish. Always double-check that your supplies are meant to be used together.

Tackling Incomplete Foil Transfers and Faded Colours

Ever printed a beautiful metallic design, only to find that bits of it are missing? That’s a classic sign of either uneven pressure or a dirty printhead.

You need to make sure your ribbon is feeding through the printer smoothly and is perfectly flat as it passes under the printhead. Any creases or wrinkles will create tiny gaps where the foil can't make proper contact.

Here are a few things I always do to ensure consistent quality:

- Clean Your Printhead: Dust and tiny bits of debris can build up on the printhead, creating dead spots where no heat is transferred. I make a habit of cleaning it regularly, following the printer manufacturer's instructions.

- Inspect Your Ribbons: Before printing, give the ribbon a quick check to ensure it's clean and free from any dust or oils from your hands.

- Check for Durability: If your printed ribbon seems to fade or wear away too easily, you might need a more durable resin foil. For help with maintaining the look of your finished products, check out our guide on ribbon care and storage.

The UK's printing industry is a real testament to quality, and your projects should be no different. The sector is a significant part of the economy, with around 8,000 printing companies across the nation as of 2018. The South West region alone accounted for a turnover of £1.197 billion, which just shows the high standards that customers expect. You can find out more about the British print industry by numbers on brightsea.co.uk.

Frequently Asked Questions About Ribbon Printing

When you get into the world of ribbon printing, a few questions always seem to pop up. I get asked these all the time, so I've put together some quick, straightforward answers to help you navigate the common sticking points and get your project running smoothly.

Can I Just Use My Normal Office Printer?

I wish it were that simple, but no, your standard inkjet or laser printer just isn't cut out for printing on fabric. An inkjet will leave you with a smudgy, bleeding mess as the ink has nothing to grab onto. A laser printer is even riskier – the intense heat from its fuser can easily melt most synthetic ribbons, which could ruin your project and do some serious damage to your machine.

For results you’ll be happy with, you really need to use a specialised thermal transfer printer or go with another professional method like screen printing.

At its core, the problem is a mismatch of materials. Office printers are built for porous paper. Ribbons, being a fabric, need specific inks or foils applied with the right amount of heat and pressure to make the design stick properly.

The demand for the right tools for the job is huge. The global market for specialised printer ribbons hit around USD 3.1 billion by 2023, and UK suppliers are a big part of that, providing high-quality, reliable products. You can dig into more of the data on the global printer ribbon market on futuremarketinsights.com.

What’s the Best Printing Method for Washable Ribbons?

If you're creating something that needs to survive the wash—like care labels for clothing or branded lanyards—durability is everything. Your go-to options here are dye-sublimation or a good quality, laundry-resistant thermal transfer ribbon.

These methods are specifically designed to infuse the ink right into the fabric's fibres. This means the design won't crack, fade, or wash away after a few spins in the machine. Just be sure to double-check that both your ribbon and your ink are rated for laundry use before you start.

How Can I Print a Repeating Pattern on a Long Spool?

Creating a continuous, seamless pattern is all about smart design. You’ll need to set up your artwork so that the end of one repetition flows perfectly into the start of the next. Most graphic design programs have 'tiling' or 'pattern' tools that make this surprisingly easy to create and test.

When it's time to print, your thermal printer's software should have an option like "continuous print" or a "repeat" setting. This tells the printer to just keep printing your design over and over again along the entire length of the ribbon spool.

Ready to bring your own beautiful custom ribbon ideas to life? Ribbons4u Ltd has a fantastic selection of high-quality ribbons and offers bespoke printing services to get your project just right. Visit us at ribbonsforyou.com to get started.

Facebook

Facebook Twitter

Twitter Pinterest

Pinterest